41 welding shop safety student worksheet

Auto Shop Safety. For Students 10th - 11th. In this vocational worksheet, students find 27 terms relating to safety in the automobile repair shop. Students may self correct by selecting the link at the end of the page. Forklift Safety 2 This material is for training use only A winch was welded on the boom of this telescoping truck without the manufacturer's approval. Design and construction of powered industrial trucks must be in compliance with the current revision of ANSI B56.1. ASME B56.1-1993, Safety Standard for Low Lift and High Lift Trucks, is the latest

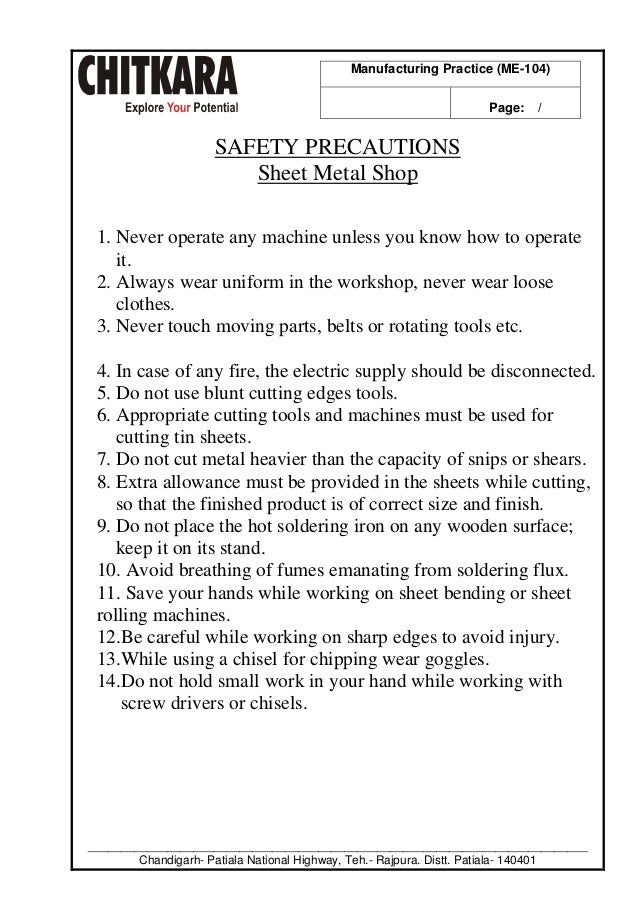

SECTION 2 - WELDING SYMBOLS WORKSHEETS (tear-out pages) ... Those welding students who are part of the AWS SENSE program will find this aspect Hands-On Print Reading for Welders especially valuable. ... •Safety Glasses. Always wear safety glasses when working with tools.

Welding shop safety student worksheet

Accompanies: Welding Shop Safety. 1. Welding Shop Safety. Workplace Safety ... devices or equipment worn by students, teachers, employees working in. Welding Shop Safety Student Worksheet Answers. 167bd3b6fa Скачать-Osmos (v2 unk 64bit os90 ok13) user hidden bfi ipa Video Anak Smp Diperkosa Rame Rame Les Choses De La Vie Partition Piano Pdf file_a63049 houzetek 3531b projection alarm clock manual the minister%27s black veil focus questions answer key Anya Dasha Crazy ... Displaying top 8 worksheets found for - Welding Shop Safety. Some of the worksheets for this concept are Shop safety, Arc welding safety guide, Safety health of welders, Basic shop safety t u d e t h a d o u t, Degrees that welding fabrication, Degrees that welding fabrication, Lesson plans for module 29101 15 w safety, Arc welder.

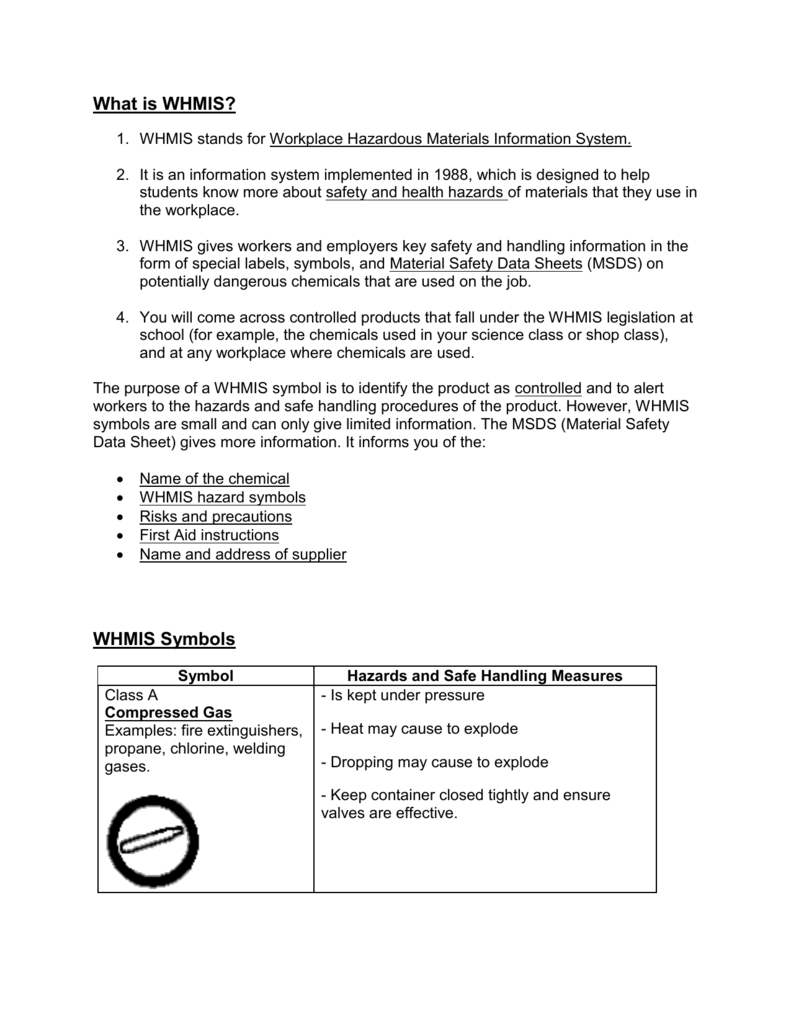

Welding shop safety student worksheet. dictates student safety. The court system understands that an instructor(s) who is doing everything reasonable and prudent and within the law (i.e., Labor and Industries / WISHA) under the given circumstances to supervise students working in a shop environment is doing what he or she should do to maintain a safe learning environment. Baylor University Shop Safety Program Introduction Machine and woodworking shops are present in many locations and departments throughout the University. The equipment located within these shops is routinely used by employees and students to complete various tasks that have the potential to result in serious injury. View ICEV Welding Workshop Safety Worksheet.pdf from ISTM 415 at Texas A&M University. Welding Shop Safety Directions: Fill in the blank. Common Causes & Prevention of Accidents 1. To prevent cuts, a welding area such as service personnel, maintenance personnel, regular visitors to the welding shop, and others. A typical material safety data sheet for a tubular arc welding electrode is shown in Figures 2, 3, and 4. Particular points of interest are highlighted to provide more data for intelligent interpretation of this information.(7)

The Z87 logo means that the safety glasses are industrial quality. 4. Equipment that requires special eye and face protection. a. Arc Welding - Welding helmet with a #10 filter lens and safety glasses. b. Oxy-Acetylene Welding - Gas welding goggles or shield (with safety glasses) with a #5 lens. View Crossword.pdf from ENGLISH 001 at New York University. Welding Shop Safety S T U D E N T C R O S S W O R D Across Down 1. Colors which designate certain parts, hazards and other actions 6. Machine safety guards are used for gears, blades, pulleys, belts, shafts, etc. Appropriate warning signs are posted for machines and area hazards. 7. Hazard assessments are performed using a shop-specific checklist, for example the Shop-Specific Hazard Assessment Checklist located in the IIPP. CHEMICAL SAFETY 1. oldest welding processes, though in recent years, it has become less popular in industrial applications. However, it is still widely used for a variety of applications. Oxy-fuel equipment is versatile, lending itself to welding, brazing, braze-welding, silver soldering, metal heating (for bending and forming) and oxy-fuel cutting.

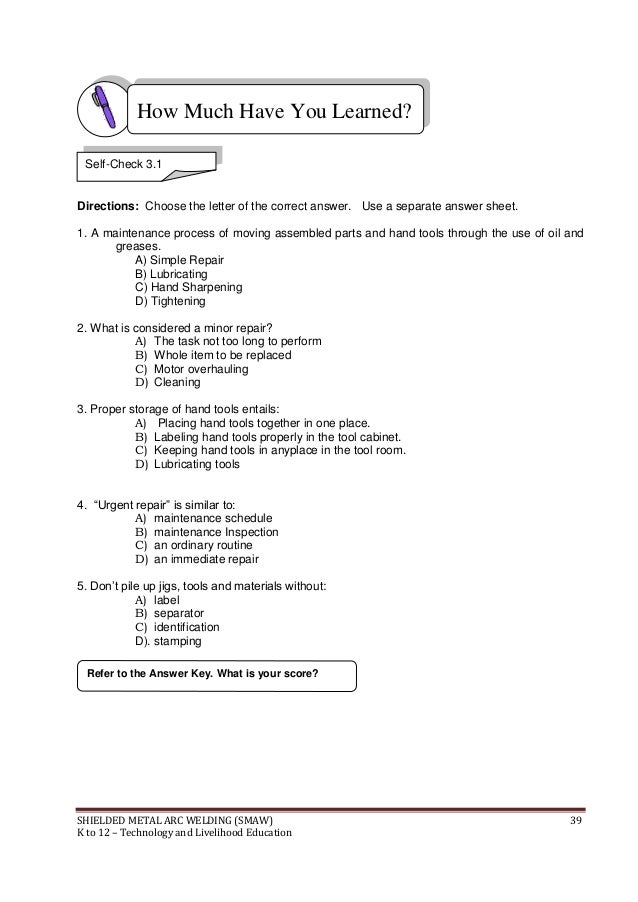

Accompanies: Basic Shop Safety 1 S T U D E N T 1. W O R K S H E E T Basic Shop Safety Directions: Fill in the blanks. _____ is the condition of being safe from risk or danger. 2. _____ are the major cause of death and injury for persons one to 37 years of age. Start studying Basic Shop Safety. Learn vocabulary, terms, and more with flashcards, games, and other study tools. All students will receive the same shop safety training, and dependent on fabrication techniques required to make the part, the student will receive training for use on Shop Fabrication (Fab) Equipment (Appendix 3), Milling Machine (Appendix 4), and/or Lathe (Appendix 5). develop a class set of welding safety guidelines. Following discussion, the class took the welding safety test and completed the attitude survey again. Observational data was collected during the intervention to measure student on-task level, and after the intervention to measure the effect on student behavior while working in the shop. The

Equipment #2 Presentation/ Activity Use the safety portion of the Welding PowerPoint to teach the students about the safety issues associated with welding. Tie in what they learned about the science of welding to understand safety issues. As you cover the safety portion of the PowerPoint have the students fill in the Safety of Welding worksheet.

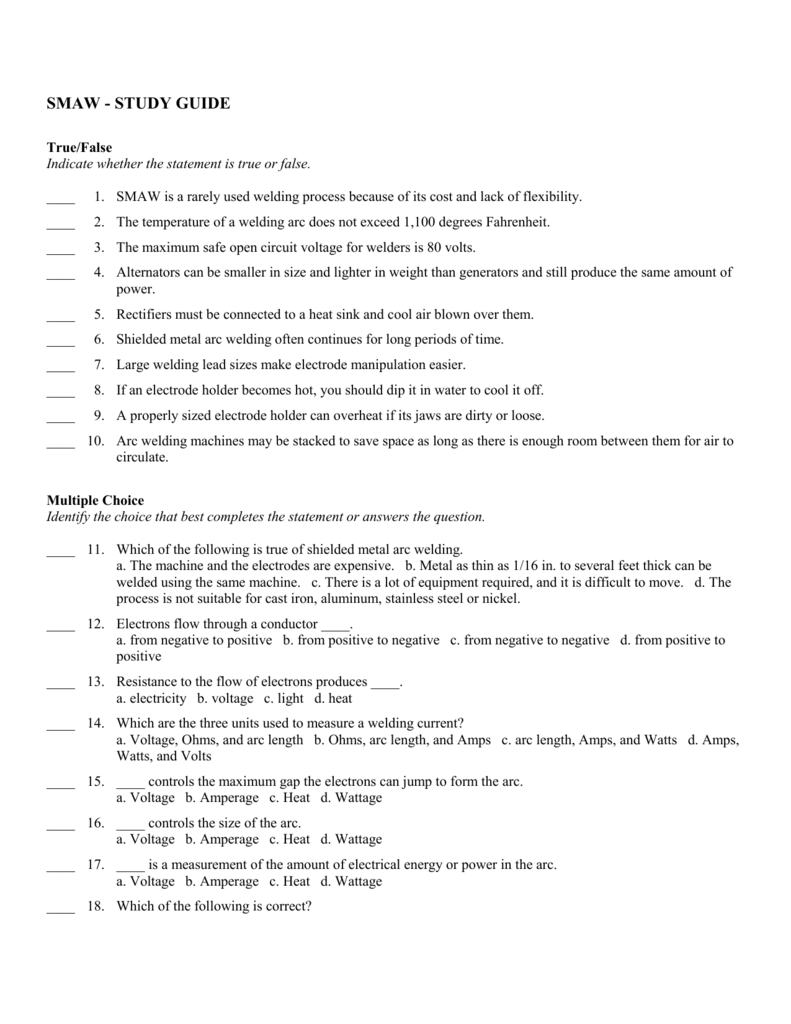

ABOUT THE COURSE. The Introduction to Welding course will provide an introduction to welding technology with an emphasis on basic welding laboratory principles and operating procedures. Students will be introduced to the three basic welding processes. Topics include hand tool and power machine use, measurement, welding career potentials and introduction to welding codes and standards.

Discuss the answers to the worksheet as a class. Related Academic Skills: 1.6.8D, E Resource #1 Resource #2 . Equipment #2 : Performance Standard 3 & 4 Assignment/ Discussion Give each student a copy of the brochure and a copy of the scavenger hunt worksheet. Have them complete the worksheet on their own time.

View Worksheet.pdf from WEB Web Page D at New York University. Welding Shop Safety Directions: Fill in the blank. Common Causes & Prevention of Accidents ...

To prevent cuts, a person should always wear proper safety equipment. ... Failure to follow the proper safety procedures will result in accidents. ... We must pay ... Rating: 4,8 · 17 reviews

Start studying Welding Shop Safety. Learn vocabulary, terms ... Sophia is designing a new welding shop for the local high school. ... 15 answers. QUESTION. Rating: 5 · 13 reviews

Who was the first to incorporate digital imaging with the CT scanner? 15 answers. QUESTION · Which foam is most commonly used at the rate ...

When conducting a job safety analysis, which jobs should be selected first in order to yield the quickest results? 2 answers. QUESTION. A.

Safety Videos. Arc welding is a safe occupation when sufficient measures are taken to protect the welder from potential hazards. When these measures are overlooked, welders can encounter such dangers as electric shock, overexposure to fumes and gases, arc radiation, and fire and explosion. This video series is a powerful resource which keeps ...

2. Always wear industrial quality eye protection when welding and cleaning welds. A number 10 filter lens is minimum for most arc welding processes. 3. Keep the welding area clean and free of tools, scrap metal, and water. 4. Make sure the work area is free of flammable, volatile, or explosive materials. (Ex. propane, gasoline, grease, and coal ...

Ask students to consider applications for which different electrode characteristics might be useful. For example, welding on thicker materials might require increased penetration, whereas welding on more delicate materials would require less penetration so as not to burn through the base metal.

2 em mèo Lùn Vện mặc đồ mới chuẩn bị đón Giáng sinh (Noel), cũng là đồ mặc năm mới của 2 em mèo. Ghé YOLO để lựa thêm đồ nhé cả nhà .

Safety Practices In Welding Worksheet Complete the following study guide. Use the Safety Practices In Welding Packet as your reference to gather the information. This worksheet is designed to help the beginning student with general safety practices in the welding shop and is also a good refresher for the advanced or returning student. Introduction

Answer Key – Welding Safety 13-026 1. Two of the more common types of welding are gas and shielded metal arc. True 2. The most common fuel used in OxyFuel Welding is acetylene. True 3. Shielded Metal Arc Welding joins two metals together by producing a laser arc between the base metals to be joined and a flux coated consumable electrode rod ...

10 answers. QUESTION. If a pilot changes permanent mailing address, how long can the pilot continue to exercise the privileges of their pilot certificate ...

Use the safety portion of the Welding PowerPoint to teach the students about the safety issues associated with welding. Tie in what they learned about the science of welding to understand safety issues. As you cover the safety portion of the PowerPoint have the students fill in the Safety of Welding worksheet.

At a conference this past weekend, a student teacher requested this information. Here it is for everyone's benefit! Unit 1 - Welding Orientation and Safety

Appendix A: Student Machine Shop Safety Manual A.1 General 1. Approved eye protection must be worn at all times in the shop area. 2. All injuries must be reported to the shop supervisor immediately. 3. Appropriate clothing is also required in the shop and when using shop equipment. Sandals and open toed shoes are prohibited.

Displaying top 8 worksheets found for - Welding Shop Safety. Some of the worksheets for this concept are Shop safety, Arc welding safety guide, Safety health of welders, Basic shop safety t u d e t h a d o u t, Degrees that welding fabrication, Degrees that welding fabrication, Lesson plans for module 29101 15 w safety, Arc welder.

Welding Shop Safety Student Worksheet Answers. 167bd3b6fa Скачать-Osmos (v2 unk 64bit os90 ok13) user hidden bfi ipa Video Anak Smp Diperkosa Rame Rame Les Choses De La Vie Partition Piano Pdf file_a63049 houzetek 3531b projection alarm clock manual the minister%27s black veil focus questions answer key Anya Dasha Crazy ...

Accompanies: Welding Shop Safety. 1. Welding Shop Safety. Workplace Safety ... devices or equipment worn by students, teachers, employees working in.

0 Response to "41 welding shop safety student worksheet"

Post a Comment